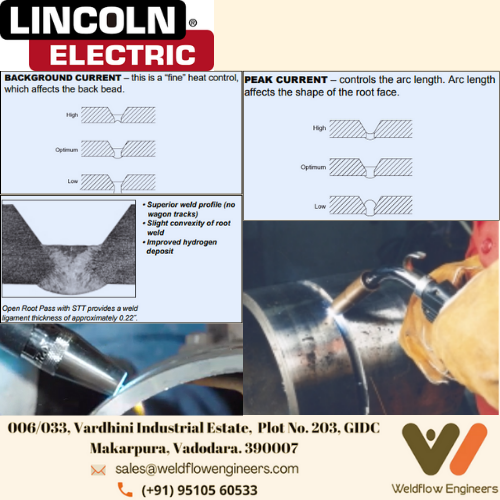

Need a Faster & an easier method to make single sided root welds for Pipe/vessel fabrication? Lincoln provides you to the precise method with its Waveform Control technology. - Surface Tension Transfer (STT) process Makes it easier to achieve a high-quality root weld in all position by producing a low hydrogen weld deposit. Eliminates the lack of penetration & poor sidewall fusion problems while using the traditional Short-Arc GMAW process. Effective for welding mild & high strength steels as well as stainless steel and related alloys. Significantly better CPT (Critical Pitting Temperature) with STT than with GTAW, when welding duplex stainless and three to four times faster travel speed than the GTAW. Efficient advantages like – Penetration control, cost reduction, flexibility, Low heat input, low hydrogen weld metal deposit, high speed & ease for Operation. Weldflow Engineers, An Authorized Distributor for The Lincoln Electric Company Content by Aniket Jadhav Weldflow Engineers #LincolnElectric #LincolnWelding #LincolnWelders #WeldWithLincoln #LincolnWeldingSolutions #LincolnWeldingEquipment #LincolnWeldingTechnology #LincolnWeldingExpertise #LincolnWeldingInnovation #LincolnWeldingQuality

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.weldflow.in/latest-update/need-a-faster-an-easier-method-to-make-single-si/110

Need a Faster & an easier method to make single si...

2023-11-28T05:17:46

Need a Faster & an easier method to make single sided root welds for Pipe/vessel fabrication? Lincoln provides you to the precise method with its Waveform Control technology. - Surface Tension Transfer (STT) process Makes it easier to achieve a high-quality root weld in all position by producing a low hydrogen weld deposit. Eliminates the lack of penetration & poor sidewall fusion problems while using the traditional Short-Arc GMAW process. Effective for welding mild & high strength steels as well as stainless steel and related alloys. Significantly better CPT (Critical Pitting Temperature) with STT than with GTAW, when welding duplex stainless and three to four times faster travel speed than the GTAW. Efficient advantages like – Penetration control, cost reduction, flexibility, Low heat input, low hydrogen weld metal deposit, high speed & ease for Operation. Weldflow Engineers, An Authorized Distributor for The Lincoln Electric Company Content by Aniket Jadhav Weldflow Engineers #LincolnElectric #LincolnWelding #LincolnWelders #WeldWithLincoln #LincolnWeldingSolutions #LincolnWeldingEquipment #LincolnWeldingTechnology #LincolnWeldingExpertise #LincolnWeldingInnovation #LincolnWeldingQuality

2023-11-28T05:17:46

Keywords

- CPT

- lack

- ease

- mild

- GTAW

- duplex

- Content

- position

- Operation

- high speed

- flexibility

- STT) process

- Aniket Jadhav

- easier method

- related alloys

- precise method

- cost reduction

- LincolnWelders

- Low heat input

- LincolnElectric

- stainless steel

- WeldWithLincoln

- Weldflow Engineers

- Penetration control

- Efficient advantages

- high strength steels

- LincolnWeldingQuality

- high-quality root weld

- Authorized Distributor

- single sided root welds

- Pipe/vessel fabrication

- LincolnWeldingExpertise

- LincolnWeldingEquipment

- LincolnWeldingSolutions

- LincolnWeldingTechnology

- LincolnWeldingInnovation

- Surface Tension Transfer

- low hydrogen weld deposit

- Waveform Control technology

- The Lincoln Electric Company

- Critical Pitting Temperature

- poor sidewall fusion problems

- low hydrogen weld metal deposit

- traditional Short-Arc GMAW process

- three to four times faster travel speed

Submit Your Enquiry